One of the most popular automatic transmissions in used cars from the Volkswagen group is the DSG DQ250 dual-clutch transmission. Is it durable? What are the impressions of it? How often should the oil be changed?

In 2003, with the introduction of the DSG transmission in the Audi TT 3.2 and Volkswagen Golf IV 3.2 R32 models, the automotive industry entered a new era. This automatic transmission enabled exceptionally fast gear changes, with minimal lag during acceleration and deceleration. The transmission’s response was nearly instantaneous, whether using the steering wheel controls or the gear lever. Thanks to the Launch Control feature, vehicle starts were also faster, allowing take-off at higher RPMs.

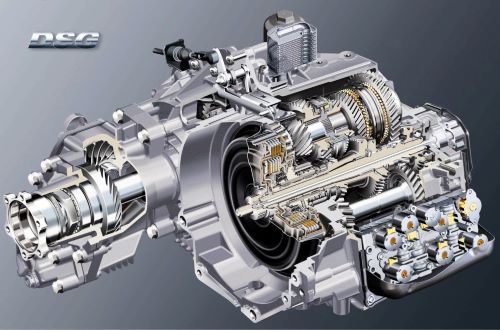

DQ250 DSG Transmission – Construction

The working speed of the DSG DQ250 transmission, known as 02E, is based on a specific construction. The transmission functions like two three-speed systems, with separate clutches for odd and even gears, allowing for exceptionally fast gear shifts. While one gear is active, the next one is already prepared for engagement, and the transmission automatically adjusts speed during deceleration. The clutch is multi-plate, similar to those in motorcycles, and the entire transmission operation is controlled by a fast mechatronic system. The transmission can handle up to 400 Nm of torque and is used with powerful engines such as the 3.2 VR6, 2.0 TFSI, as well as powerful diesel engines like the 2.0 TDI. There is also a more advanced version of the transmission, the DQ400e, which is used in plug-in hybrids.

DQ250 DSG Transmission – Common Problems

Does the DSG DQ250 have any downsides? It weighs 93 kg. Multi-plate clutches are more complex and expensive solutions compared to dry clutches, which can lead to higher power losses. As a result, a 7-speed DSG DQ200 was developed for weaker models, which has proven to be less durable compared to the DSG DQ250.

Despite its age, the DSG DQ250 still receives good ratings—with proper maintenance and careful use, it can surpass half a million kilometers. Issues with gears inside the transmission or the housing (such as cracks) are rare and usually occur due to extreme usage conditions or neglecting maintenance. At higher mileage, bearing problems may arise. Additionally, one problem can lead to another, increasing repair costs. It’s important to respond quickly to any metallic sounds, squeaks, sounds during load changes, and irregularities in gear shifts, such as jerking, extended shift times, or errors.

One should also be prepared for the natural wear of clutch packs and the dual-mass flywheel. It’s difficult to determine the exact mileage at which this will happen, as it heavily depends on vehicle use. Typically, repairs are not necessary before 200-250 thousand kilometers. In diesel engines, the dual-mass flywheel may last less than the clutch disc. Symptoms include vibrations and mechanical noises during engine start and shutdown.

The most common issues relate to the DSG DQ250 transmission controller, known as the mechatronics, which can cause the transmission to enter emergency mode. Failures of electromagnetic valves, speed sensors, and oil pressure regulators can occur within the transmission controller. Additionally, short circuits may sometimes happen within the controller—this issue is mainly related to the oldest types of DQ250 transmissions. The transmission has become popular enough that specialized services for its maintenance have mastered diagnostics and repairs.

DQ250 DSG Transmission – Tuning and Controller Adaptation

The initial settings of the DSG DQ250 transmission controller were not bad—in the first version, the transmission did not tend to keep the engine at excessively low RPMs, as newer versions of DSG transmissions do. However, over time, the settings evolved to achieve lower carbon dioxide emission levels. Reducing RPMs down to 1200 can be detrimental to transmission parts, especially the dual-mass flywheel.

It’s worth noting that it’s possible to reprogram the shift strategy if the factory settings don’t suit the driver. Additionally, other changes can be made, including shortening shift times.

Also crucial for proper gear shifting and the longevity of clutch packs is the so-called clutch adaptation, which can be performed using a service computer. In this process, the electronics analyze and record parameters such as pressure strength, synchronization points, and component movement range.

The DSG DQ250 transmission uses oil to fill its interior and lubricate the clutches. This is critical because clutch linings wear down and can contaminate the oil. It’s recommended to change the oil every 60,000 to 80,000 km. For this transmission, oil with VW approval G 052 182 A2 is required, and about 6 liters are needed for replacement. Maintenance services emphasize that dynamic oil replacement is possible but not efficient, as the gravity method allows for the replacement of most lubricants, while DSG transmissions do not have a torque converter that retains large amounts of oil like traditional automatic transmissions.